SDA Series aluminium alloy acting tinne type pneumatyske standert kompakte lucht silinder

Produkt Beskriuwing

De silinder is fan tinne ûntwerp en lytse totale ôfmjittings, dat is geskikt foar gelegenheden mei beheinde romte. Syn wurkdruk is meastentiids tusken 0.1 ~ 0.9mpa, dat hat hege wurkje effisjinsje.

SDA rige silinders hawwe betroubere sealing prestaasjes en glêde beweging skaaimerken. It oannimt produksjetechnology mei hege presyzje om de dichtheid en krektens fan 'e silinder te garandearjen. Tagelyk, de silinder is foarsjoen fan in buffer apparaat, dat kin ferminderjen de ynfloed en lûd yn beweging.

Technyske spesifikaasje

| Bore Grutte (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Acting Mode | Double Acting | |||||||||

| Working Media | Cleaned Air | |||||||||

| Wurkdruk | 0.1~0.9Mpa(kg/cm) | |||||||||

| Bewiis druk | 1,35 Mpa (13,5 kgf/cm) | |||||||||

| Wurktemperatuer | -5 ~ 70 ℃ | |||||||||

| Buffermodus | Mei | |||||||||

| Port Grutte | M5 | 1/8 | 1/4 | 3/8 | ||||||

| Body Materiaal | Aluminiumlegering | |||||||||

| Sensor Switch | CS1-J | CS1-G CS1-J | ||||||||

Beskriuwing; SDA100 tosken as 25 yn 'e silinder zuigerstang, en de tosken foar Ф 32 zuigerstang

100≤ST<150, en gjin magnetysk, silinderlingte 10.

ST≥150, gjin saak mei of sûnder magnetysk, silinder lingte 10.

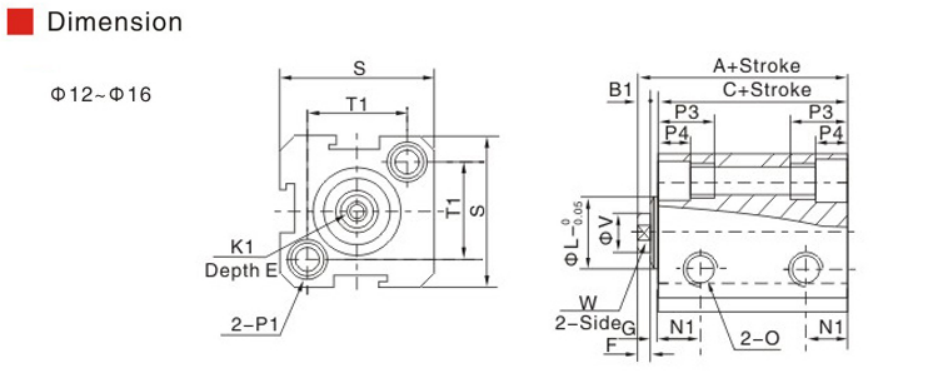

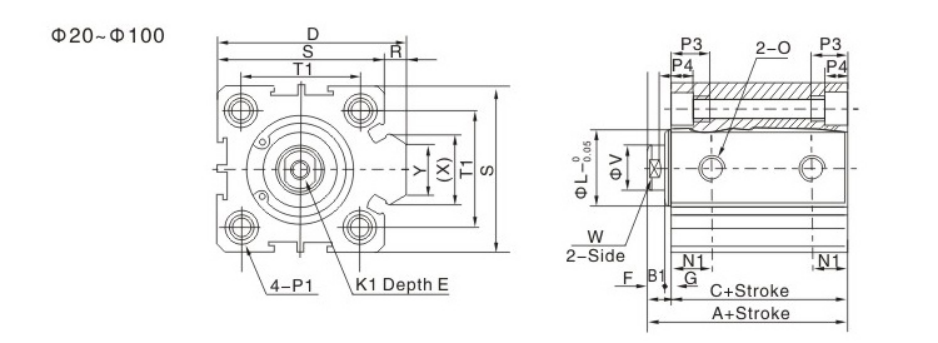

| Bore Grutte (mm) | Standert Type | Magnet Type | D | B1 | E | F | G | K1 | L | N1 | N2 | O | ||

| A | C | A | C | |||||||||||

| 12 | 22 | 17 | 32 | 27 | / | 5 | 6 | 4 | / | M3X0.5 | / | 7.5 | 5 | M5X0.8 |

| 16 | 24 | 18.5 | 34 | 28.5 | / | 5.5 | 6 | 4 | 1.5 | M3X0.5 | 11 | 8 | 5.5 | M5X0.8 |

| 20 | 25 | 19.5 | 35 | 29.5 | 36 | 5.5 | 8 | 4 | 1.5 | M4X0.7 | 14 | 9 | 5.5 | M5X0.8 |

| 25 | 27 | 21 | 37 | 31 | 42 | 6 | 10 | 4 | 2 | M5X0.8 | 17 | 9 | 5.5 | M5X0.8 |

| 32 | 31.5 | 24.5 | 41.5 | 34.5 | 50 | 7 | 12 | 4 | 3 | M6X1 | 22 | 9 | 9 | G1/8 |

| 40 | 33 | 26 | 43 | 36 | 58,5 | 7 | 12 | 4 | 3 | M8X1.25 | 28 | 9.5 | 7.5 | G1/8 |

| 50 | 37 | 28 | 47 | 38 | 71.5 | 9 | 15 | 5 | 4 | M10X1.5 | 38 | 10.5 | 10.5 | G1/4 |

| 63 | 41 | 32 | 51 | 42 | 84,5 | 9 | 15 | 5 | 4 | M10X1.5 | 40 | 12 | 11 | G1/4 |

| 80 | 52 | 41 | 62 | 51 | 104 | 11 | 20 | 6 | 5 | M14X1.5 | 45 | 14.5 | 14.5 | G3/8 |

| 100 | 63 | 51 | 73 | 61 | 124 | 12 | 20 | 7 | 5 | M18X1.5 | 55 | 17 | 17 | G3/8 |

| Bore Grutte (mm) | P1 |

| 12 | Dûbele kant: Ф6.5 ThreadM5 * 0.8 Troch gat Ф4.2 |

| 16 | Dûbele kant: Ф6.5 ThreadM5 * 0.8 Troch gat Ф4.2 |

| 20 | Dûbele kant: Ф 6.5 ThreadM5 * 0.8 Troch gat Ф4.2 |

| 25 | Dûbele kant: Ф 8.2 ThreadM6 * 1.0 Troch gat Ф4.6 |

| 32 | Dûbele kant: Ф 8.2 ThreadM6 * 1.0 Troch gat Ф4.6 |

| 40 | Dûbele kant: Ф10 ThreadM6 * 1.25 Troch gat Ф6.5 |

| 50 | Dûbele kant: Ф11 ThreadM6 * 1.25 Troch gat Ф6.5 |

| 63 | Dûbele kant: Ф11 ThreadM8 * 1.25 Troch gat Ф6.5 |

| 80 | Dûbele kant: Ф14 ThreadM12*1.75 Troch gat e:Ф9.2 |

| 100 | Dûbele kant: Ф17.5 ThreadM14*12 Troch gat Ф11.3 |

| Bore Grutte (mm) | P3 | P4 | R | S | T1 | V | W | X | Y |

| 12 | 12 | 4.5 | / | 25 | 16.2 | 6 | 5 | / | / |

| 16 | 12 | 4.5 | / | 29 | 19.8 | 6 | 5 | / | / |

| 20 | 14 | 4.5 | 2 | 34 | 24 | 8 | 6 | 11.3 | 10 |

| 25 | 15 | 5.5 | 2 | 40 | 28 | 10 | 8 | 12 | 10 |

| 32 | 16 | 5.5 | 6 | 44 | 34 | 12 | 10 | 18.3 | 15 |

| 40 | 20 | 7.5 | 6.5 | 52 | 40 | 16 | 15 | 21.3 | 16 |

| 50 | 25 | 8.5 | 9.5 | 62 | 48 | 20 | 17 | 30 | 20 |

| 63 | 25 | 8.5 | 9.5 | 75 | 60 | 20 | 17 | 28.7 | 20 |

| 80 | 25 | 10.5 | 10 | 94 | 74 | 25 | 22 | 36 | 26 |

| 100 | 30 | 13 | 10 | 114 | 90 | 25 | 22 | 35 | 26 |